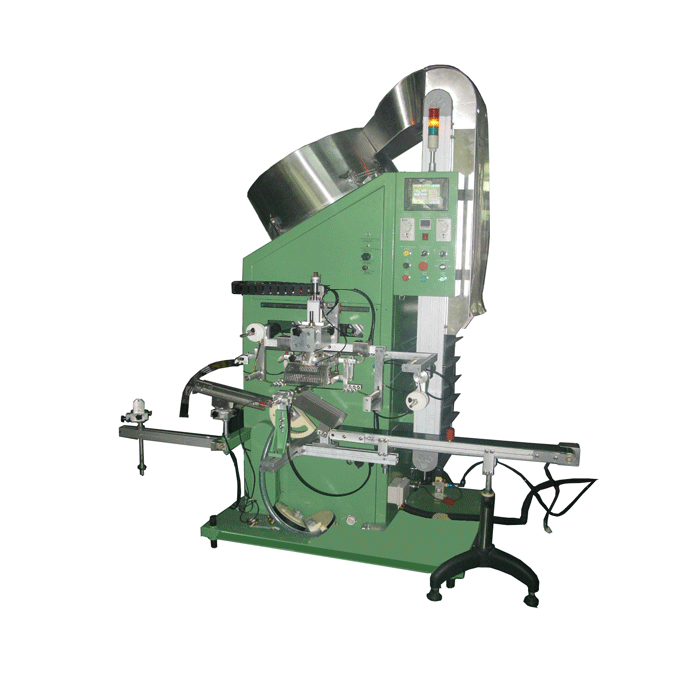

Model No.︰H-TAR

Brand Name︰KC

Country of Origin︰China

Unit Price︰US $ 22264 / pic

Minimum Order︰1 pic

Most of the containers need to be closed with lids to achieve the purpose of long-term preservation of products. The hot stamping of lids is also a decoration issue that is generally concerned in the industry. The hot stamping of lids is divided into side stamping and top stamping. The structure of the machine is roughly the same, except that During the process, the hot stamping on the top of the bottle cap adopts flat stamping, and the ironing head only moves up and down, while the hot stamping on the side of the bottle cap requires the rotation of the fixture and the left and right movement of the ironing head.

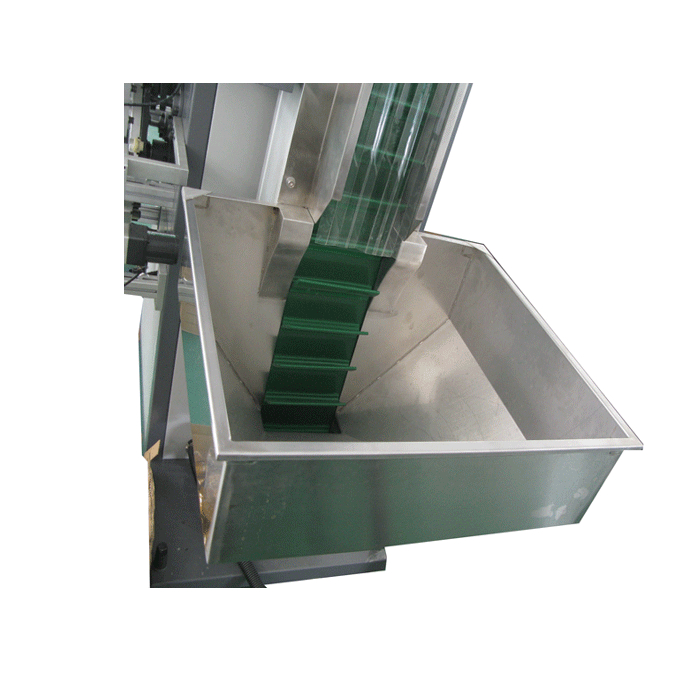

Automatic bottle cap hot stamping usually consists of automatic crawler feeding system, prepress processing system, positioning system, workbench, hot stamping system, and automatic unloading system. Because bottles and bottle caps are widely used in all aspects of life and are used in large quantities, the speed requirements for automatic hot stamping machines are very high. It is widely used in plastic packaging, medicine, cosmetics, stationery, wine, washing supplies and other industries.

|

Full automatically cap-side Line-type hot stamping Machine //Structure |

|

|

Feeding |

Crawling robot |

|

Initial position |

Sensor control , Guide rail |

|

Working table |

8 stations rotating disk, index plate control |

|

Surface treatment |

Heat air |

|

Top-bottom identification |

Sensor and Machine device |

|

Press |

Vertical press |

|

Temperature control |

IR Heater, automatically controlling |

|

Foil collecting |

Automatically collecting |

|

Blanking |

Automatically |

|

Full automatically cap side line-type hot stamping machine //Usage and characters |

|

|

Guide |

|

|

Application fields |

|

|

Full automatically cap-side hot stamping Machine //Parameter |

|

|

Technical parameters |

|

|

Works supply |

|

|

Package list |

|

|

H.S.Code |

8443198000 |

|

Certificate |

CE |

|

Full automatically cap-side hot stamping machine //Advantage |

|

|

Function |

|

Application︰

Most of the containers need to be closed with lids to achieve the purpose of long-term preservation of products. The hot stamping of lids is also a decoration issue that is generally concerned in the industry. The hot stamping of lids is divided into side stamping and top stamping. The structure of the machine is roughly the same, except that During the process, the hot stamping on the top of the bottle cap adopts flat stamping, and the ironing head only moves up and down, while the hot stamping on the side of the bottle cap requires the rotation of the fixture and the left and right movement of the ironing head.

Automatic bottle cap hot stamping usually consists of automatic crawler feeding system, prepress processing system, positioning system, workbench, hot stamping system, and automatic unloading system. Because bottles and bottle caps are widely used in all aspects of life and are used in large quantities, the speed requirements for automatic hot stamping machines are very high. It is widely used in plastic packaging, medicine, cosmetics, stationery, wine, washing supplies and other industries.