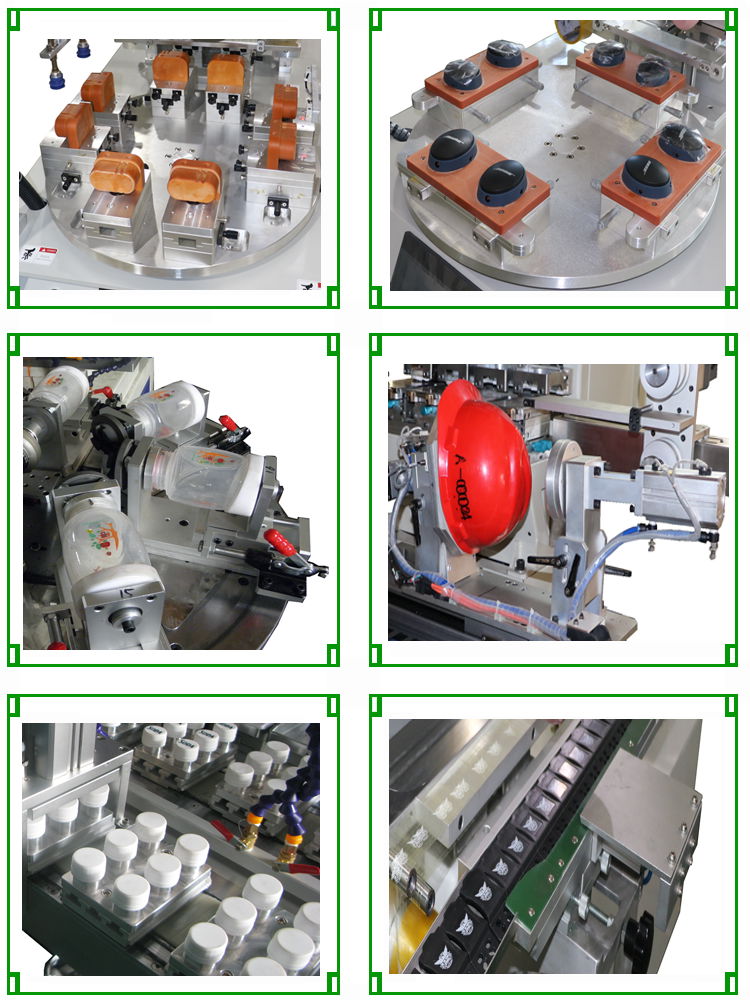

Fixture

Different products require different fixture which orientation support and overprint function in the process of pad printing, screen printing or hot stamping.

Pad printingmachine fixture, rotating pad printer fixture, shuttle pad printer fixture,automatic pad printer fixture, Bottle cap pad printer fixture,helmet fixture for pad printer

In order to achieve printing on special-shaped substrates, they must be fixed according to certain requirements, so that the relative positions of the printing surface and the embossing parts meet the requirements of the printing process. The device that keeps the printed surface of the printed product in line with the requirements of the printing process is called a fixture. In the special printing industry, the shape of the substrate can be said to vary greatly, and the position of the printing surface on the substrate is also different. Whether it can be printed accurately according to the requirements of the model, the fixture plays a key role. For some irregular plastics, electronic products and other substrates, it is costly and troublesome to make positioning devices by machining; while casting is simple, fast and easy to position; therefore, it is very useful in the special printing industry. widely.

Fixture production requirements

Deformation of the workpiece can cause deformation of the print.

is as parallel as possible to the printing plate surface. The printed material depends on the printing pressure to obtain the imprint. When designing the machine, the pad printing head, scraper, and hot stamping head are designed to be perpendicular to the plane of the printing plate to obtain the maximum printing pressure. Therefore, when making the positioning device, try to ensure that it is consistent with The printing plate surface is parallel to keep the printing pressure between the stamping parts and the substrate in an optimal state.

Can be installed on the table of the printing press. Whether it is a pad printing machine, a screen printing machine, or a hot stamping machine, the workbench is designed with a wire hole for installing a positioning device, and the size of the positioning hole of the positioning device must meet the requirements.

To achieve mass production, uninterrupted loading and unloading is very important. In the case of ensuring accurate positioning, the positioning method of the workpiece on the positioning device should be as simple as possible.

Accurate color registration is the basic requirement of printed matter. For the positioning device, the workpiece cannot move horizontally or vertically during the printing process. For the circular surface, the rotation in the circumferential direction must be prevented.