Screen printing machine

There are many types of fully automatic screen printing machines. The common classification methods and specific types are as follows:

1. Classification by the type of printed substrate:

• Paper-type fully automatic screen printing machine: mainly used for printing on paper, such as various book covers, posters, leaflets, etc. This type of screen printing machine has good adaptability to paper transportation, positioning, and ink adhesion.

• Plastic-type fully automatic screen printing machine: suitable for printing on plastic substrates, such as plastic bottles, plastic containers, plastic films, etc. Since the surface properties of plastics are different from other materials such as paper, this type of screen printing machine will have corresponding adjustments and optimizations in ink selection, printing pressure control, etc. to ensure printing quality. For example, it is widely used in cosmetic packaging, food packaging and other fields.

• Ceramic-type fully automatic screen printing machine: specially used for printing on ceramic products, such as ceramic tableware, ceramic decorations, tiles, etc. The surface of ceramic materials is relatively rough, and the requirements for ink adsorption and printing firmness are high, so this type of screen printing machine is usually equipped with special inks and printing processes to meet the needs of ceramic printing.

• Glass automatic screen printer: mainly used for printing on glass substrates, such as glassware, glass doors and windows, glass crafts, etc. The glass surface is smooth, and the printing accuracy and ink adhesion are required to be high. At the same time, the fragility of glass needs to be considered, and the stability and safety of operation must be ensured during the printing process.

• Circuit board automatic screen printer: used for the production of printed circuit boards (PCBs), widely used in the electronics industry. The printed patterns on the circuit boards require high precision and clear lines, so this type of screen printer needs to have high-precision positioning and printing capabilities, and can accurately print ink at the designated position on the circuit board.

• Metal automatic screen printer: suitable for printing on metal substrates, such as metal sheets, metal products, metal packaging, etc. The hardness of the metal surface is high, and the wear resistance of the screen printer's scraper and screen is required to be high. At the same time, special inks and curing methods are required to ensure the firmness of the printed pattern.

• Textile automatic screen printer: mainly used for printing on textiles, such as clothing, fabrics, curtains, etc. Textiles are soft and easy to deform, so this type of screen printing machine needs to have a good fabric conveying and positioning system to ensure the accuracy of printing.

2. Classification by the structure and working mode of the printing machine:

• Flat screen printing machine: It uses a flat screen plate to print on a flat substrate. It is the most common type of fully automatic screen printing machine. Its working principle is that the squeegee presses the printing plate and moves horizontally, and the substrate is changed by the rise and fall of the printing plate. It is suitable for printing various flat materials, such as paper, plastic sheets, metal plates, etc.

• Curved screen printing machine: It uses a flat screen plate to print on a round or curved substrate. The squeegee is usually fixed, the printing plate moves horizontally, and the substrate rotates with the same linear speed of the printing plate. It can be printed on various curved objects, such as cylindrical containers, spherical objects, irregular surfaces, etc.

• Rotary fully automatic screen printing machine: It uses a cylindrical screen plate, and a wedge-shaped squeegee or squeegee roller is installed inside the cylinder. The linear speed of the printing plate rotation and the movement of the substrate is the same. This type of screen printer has a fast printing speed and high efficiency, and is suitable for large-scale continuous printing operations. For example, it is widely used in the printing of materials such as plastic films and paper rolls.

• Elliptical fully automatic screen printer: It has a rotary structure, coaxial platform rotation, variable frequency electric printing, and mechanical fast positioning. It has many workstations and an expandable structural design. It can combine printing and drying workstations according to actual conditions. It is often used for printing clothing pieces and can print paste, water slurry, ink and other slurries.

3. Classification by other special functions or application areas:

• IT window glass fully automatic screen printer: Developed and designed to meet the needs of the IT industry for high-precision, intelligent and automated screen printing equipment, it can automatically transfer and has machine vision positioning and printing functions, and can automatically connect with the previous and next processes.

• Solar crystalline silicon cell fully automatic screen printer: It consists of fully automatic film loading, film storage, automatic film feeding, machine vision automatic positioning, automatic printing, automatic transfer and film output systems, and is mainly used for screen printing of solar crystalline silicon cells.

• PCB process fully automatic screen printer: designed for the circuit board (PCB)'s demand for high-precision, intelligent, and automated screen printing equipment, it has CCD visual recognition automatic alignment, automatic transmission, and printing functions, and can automatically connect with the previous and next processes.

• Optoelectronic Display Technology Fully Automatic Screen Printer: Horizontal design, consisting of three parts: import, print, and export. It uses CCD visual automatic alignment, high precision, and is suitable for high-precision fully automatic screen printing of flat substrates, such as PLC, EL, LED, IMD, glass, PCB circuit boards, etc.

|

Sorts

|

Characteristic

|

Application

|

Model

|

Ink type

|

|

| Sheet -fed screen printing machine | |||||

|

Shee-fed

Screen

printer

|

Mechanical control,working speed fast, screen plate drop with slant angle.

|

Packaging decoration,credit card Screen printing.

|

S-JY6090PV

S-JY80120PV

|

UV

Solvent base

|

|

|

Mechanical, Pneumatic control, screen plate drop with vertical direction

|

Gify case, credit card, , Household appliances,Plastics accessories , Photo frame, Membrane circuit, Photovoltaic, Electron.

|

S-3848PV

S-4565PT

S-4060PT

PS-6080PV

S-81110F

|

UV

Solvent base

|

||

|

Auto feeding, UV Drying or IR Heating system

|

Ceramic,Building materials ,Glass,Paper industry,Credit card, Package case.

|

|

Heat-set ink

Solvent base

UV

|

||

|

Flat

screen

printer

|

|

Auto feeding, Tension control, Rectification device, Sensor controlling system.

|

Web paper, webbing, Film,Label screen printing ,nonwovens , Rubber.

|

|

Heat set ink

UV

Solvent base

|

|

Curve

screen

printer

|

Pneumatic controlling,, screen print drop or table rise, speed slow, The table install rotary device

|

Plastics container, metal, Glass container, all round objects , Auto industry, Plastics industry, articlesevery day

|

S-75S

S-125S

S-220S

|

Solvent base

UV

|

|

|

Auto feeding system, Transmitting device, UV Drying system, and use UV ink, overprint is easily, high speed.

|

Plastics container, soft tube, cosmetic case , bottle cap.

|

SZD-1022

SZD-VR12UV

|

UV

|

||

|

Turn-

workbench

Garment

screen

printer

|

Workbench and screen plate rotate around the center axis,Floor space small,.

|

Clothing, Garment, CD.

|

SM6-4565

SM8-5070

|

Heat set ink

|

|

|

Oval-type

|

Workbench rotate around oval orbit , floor space big. Full automatically controling and IR Drying

|

Clothing, Garment, CD.

|

|

Heat set ink

|

|

Screen printing fixture

1. Definition

The fixture of the screen printer is used to fix and position the substrate (such as electronic product housing, plastic parts, glass sheets, etc.), ensuring that the substrate is accurately and stably positioned during the screen printing process, and ensuring the accuracy and consistency of the printed pattern.

2. Types

• Plane fixture:

• Used to fix flat substrates, such as paper, plastic plates, etc. It is usually a flat metal or plastic plate with positioning pins or positioning holes on it, which can be precisely positioned by matching with the corresponding holes or edges on the substrate.

• Curved fixture:

For curved products, especially cylindrical products, the fixture should be able to ensure the fixation of the central axis direction and the rotation in the circumferential direction. Generally, gear racks are used in conjunction with the fixture. For conical products, the fixture should ensure that the product rotates along the fan-shaped track. The curved fixture should have a blowing function for soft bottles!

3. Design points

• Accuracy requirements: The positioning accuracy of the fixture is the key. In order to ensure the accuracy of the printed pattern, the dimensional tolerance of the positioning part of the jig (such as positioning pins, positioning holes, etc.) should be controlled within a very small range, and the general accuracy can reach ±0.05 - ±0.1mm, so as to ensure that the position error of the substrate after each placement is extremely small.

• Material selection: The material of the jig should be selected according to the nature of the substrate and the requirements of the screen printing process. For general flat printing, metal (such as aluminum alloy) or engineering plastic (such as ABS plastic) are commonly used materials, which have good strength and stability. If it is used for high-precision electronic product printing, high-precision processed stainless steel materials may be used to ensure the long-term stability and accuracy of the jig. For the jig part that needs to be frequently exposed to chemical inks, the material also needs to have a certain degree of corrosion resistance. Some screen-printed products have complex and irregular shapes, and the jig can be made by casting unsaturated polyester resin.

• Compatibility with screen printers: The size and installation method of the jig should match the printing platform and workflow of the screen printer. The fixture should be easy to install and remove, and should not affect the normal operation of the screen printing machine after installation, such as the movement of the squeegee, the lifting and lowering of the screen, etc.

The structure of the screen printing machine is constantly changing with the changes in the market. The main change is the change in the movement form of the workbench. The change in the movement form of the workbench makes the printing from intermittent to continuous, realizing the relative automation of the printing process.

1) Rotary screen printing machine

The workbench of the rotary screen printing machine has multiple even-numbered stations forming a disc, which are arranged and rotated along the central axis and enter the printing device in turn. Pre-press devices such as flame treatment devices, plasma treatment devices, electrostatic dust removal devices, and post-press devices such as tunnel drying devices and UV curing devices can be set between the stations to make the printing process more perfect.

2) Sliding table screen printing machine

The sliding table screen printing machine refers to a workbench that can move along the guide rail, or move left and right, or move forward and backward. When moving out, the product can be removed and placed, and when moving into the printing position, printing can be performed. The sliding table screen printing machine avoids contact between the operator and the printing device and improves safety.

3) Conveyor belt screen printer

A conveyor belt screen printer refers to a screen printer installed with a conveyor belt. The conveyor belt can run continuously. The operator can place the products on the conveyor belt at a certain interval, and the products will be transported to the printing position in sequence.

4) Flip screen printer

A screen printer can only print on one plane of a product at a time. If the workbench can rotate 90 degrees or 180 degrees, the screen printer can print on different planes of a product. For example, square containers such as beer plastic frames and storage plastic frames are often used for this type of screen printer. Its workbench is controlled by a servo motor and can rotate freely in the vertical direction.

Why is a robot installed on a screen printing machine?

The robot installed on a screen printing machine is an automated auxiliary equipment designed for printing scenarios. It replaces some manual operations, realizes partial automation, and reduces the labor intensity of the operator: At present, the more mature cases of installing robots are: installing robots on oblique arm screen printing machines, installing robots on vertical screen printing machines, and installing robots on turntable flat screen printing machines.

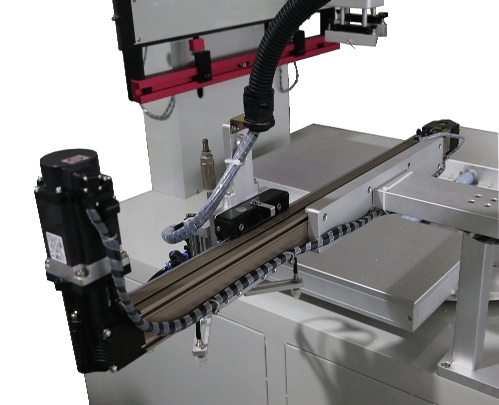

Structure of the robot

Actuator:

For common flat parts (paper, glass, metal plates) in screen printing, vacuum suction cups are often used to suck the products; for products with specific shapes and certain quality, pneumatic grippers may be used to grab the products

Moving arm:

The end effector needs to be moved to the specified position by the moving arm to place the product. The moving distance, such as up and down lifting, horizontal translation, rotation fine-tuning, etc., can be adjusted. The structure is mostly a multi-dimensional action of a linear module + articulated arm.

Drive system:

The driving robot can be a servo motor or a cylinder, which is matched with a reducer, solenoid valve, etc. to control the movement amplitude and strength.

Control system:

Through PLC linkage with the screen printer host, receiving the signal of the printer, triggering the robot to move, and ensuring the accuracy of grabbing and placing through the position sensor (the error is usually controlled within 0.1-1mm).

Program

The core of the screen printer robot is "automatic loading and unloading according to the preset program, synchronized with the printing process":

1. Loading stage: The robot grabs the workpiece to be printed from the silo or conveyor belt, places it accurately on the workbench of the screen printer through the moving arm, and triggers the positioning sensor to confirm.

2. Printing coordination: After the workpiece is positioned, the robot returns to the waiting area to avoid interfering with the work of the screen printing head; after printing is completed, the receiving signal starts again.

3. Unloading stage: The robot moves to the workbench, grabs the printed workpiece, and transfers it to the IR drying area or UV drying area to complete a cycle.

The oblique-arm screen printer + robot + UV curing machine production line in the local UV process; the vertical screen printer + robot + IR tunnel drying line in the thermal transfer film production process; the turntable flat screen printer + robot + UVLED curing machine production line in the UV process of household appliance panels are very mature examples of adding robots.